Grey, blue, green... understanding the rainbow of hydrogen colours

Nowadays, it is common practice among the media to associate hydrogen with a colour, such as grey, green, blue and black. This informal labelling system provides an easy way of identifying where the hydrogen actually comes from. This information is especially important, since depending on how it is produced, hydrogen will either contribute massively to climate change or play a key role in moving the energy transition forward. Take a closer look at the colour palette for a clearer insight.

On the same focus

What are the uses for hydrogen in today's world and the future?

Hydrogen sector: investing in a net zero future

Hydrogen production: matching each colour with its impact

Grey, brown and black: hydrogen from hydrocarbons

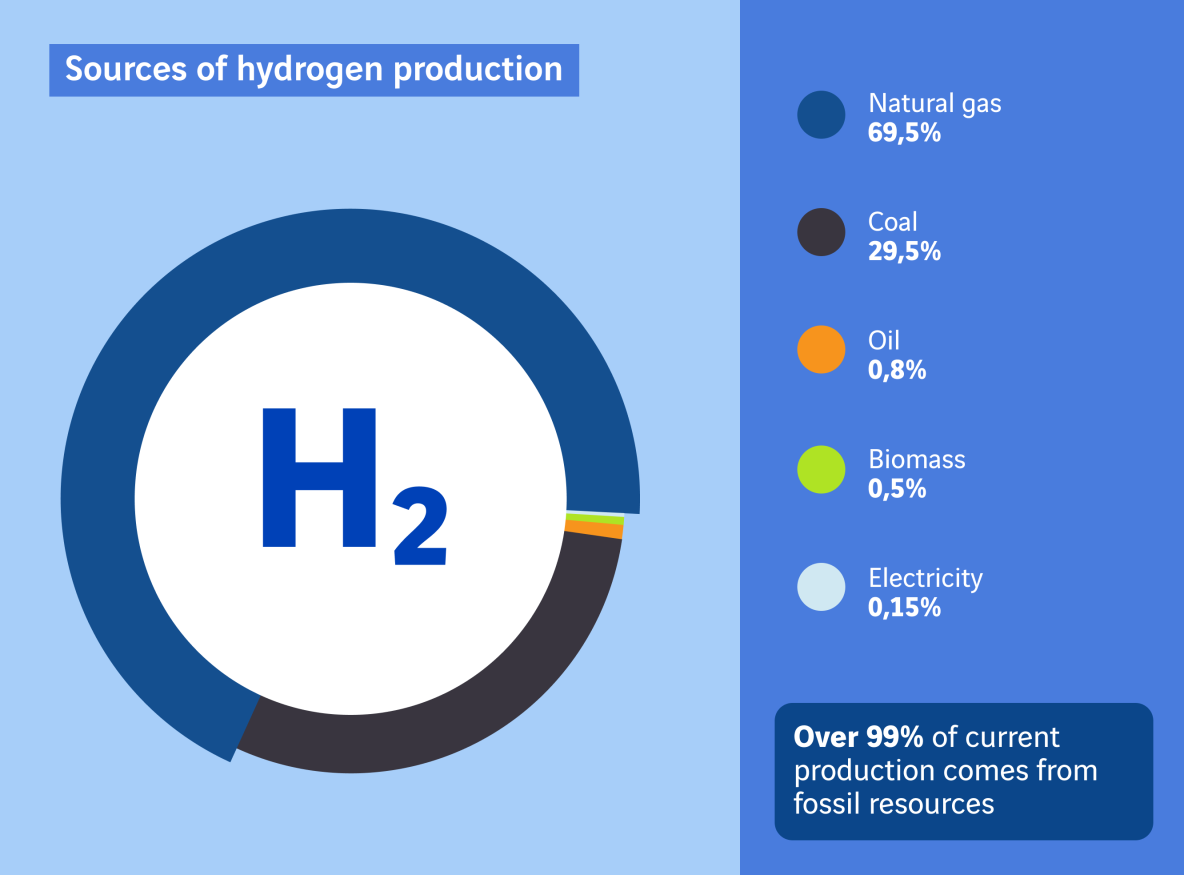

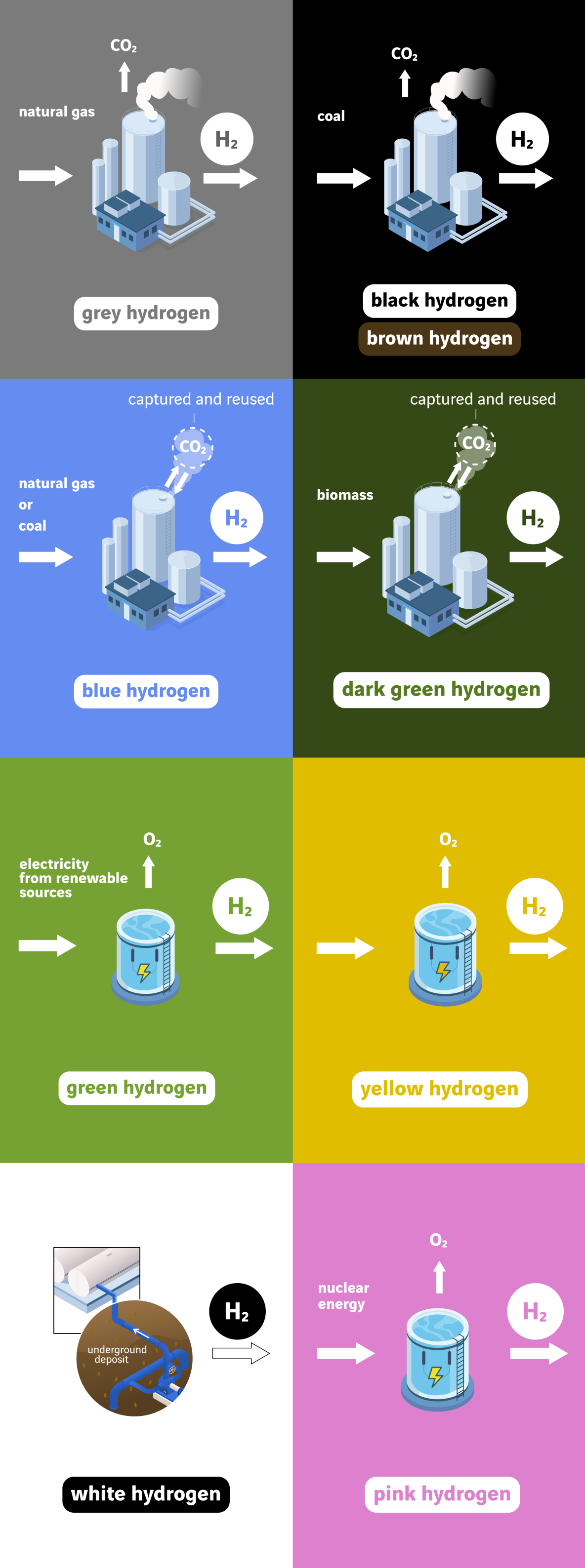

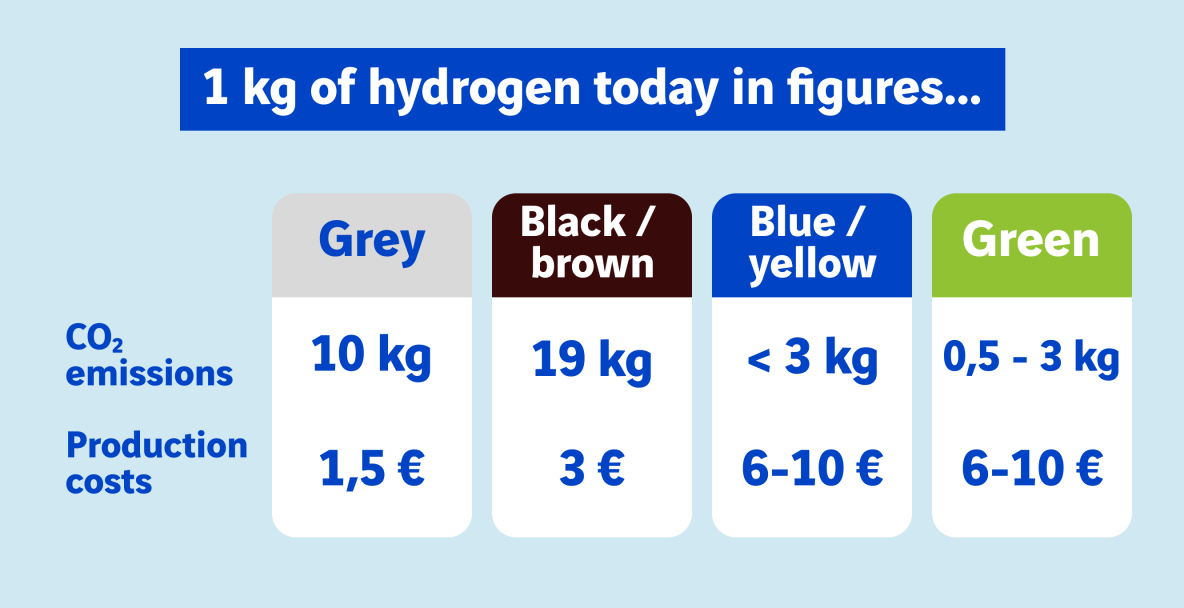

By definition, hydrocarbons are compounds containing carbon and hydrogen atoms, which need to be separated in order to extract only the hydrogen. At the present time, nearly all of global hydrogen demand is fulfilled via processes that use hydrocarbons. "Grey" hydrogen is created from natural gas using steam reformation. "Brown" and "black" hydrogen is produced via a coal gasification process.

Blue: capture the carbon emissions from grey hydrogen!

"Blue" hydrogen is produced from a variant of the steam reforming process in petrochemical plants fitted with carbon capture, utilisation and storage systems (CCUS). The carbon emitted by the process is captured and either put into long-term storage or reused for industrial purposes.

Pink, yellow and green: hydrogen from water electrolysis

Hydrogen is abundantly available in water. Hydrogen can be produced on an industrial scale by means of a physically simple electrolysis process that involves passing a current through the water to "split" its H2O molecule.

In the case of pink hydrogen, the electricity required for the process is supplied by nuclear power plants. In the European Union, nuclear energy was included as a sustainable energy production source in the EU taxonomy adopted in July 2022.

Yellow hydrogen is also produced through electrolysis using electricity from the local grid, which may therefore be produced from fossil, nuclear or renewable energy.

Green hydrogen is made from renewable electricity (solar, wind, hydropower, etc.).

What about "dark green" hydrogen? The special case of biomass

Just like hydrocarbons, the organic molecules in biomass are rich in carbon and hydrogen. As such, hydrogen can be produced by fermenting or gasifying agricultural, forest, agribusiness and household waste. This technology is said to be "carbon neutral". The carbon emitted by the process is equivalent to the carbon that would have been released into the atmosphere if the waste had been left to degrade naturally.

What challenges face low-carbon hydrogen production?

The reason why the "colour" of the hydrogen is so important is that this chemical element will play a key role in driving the energy transition. In its Net Zero Emissions by 2030 scenario, the International Energy Agency (IEA) is expecting global hydrogen demand to almost double to over 175 Mt a year. According to some predictions, that figure will top 1,200 Mt by 2050. Such explosive growth in demand can only be sustained if green and blue hydrogen is massively developed at the expense of grey hydrogen. To deploy enough CCUS facilities and electrolysers to achieve a pathway to net zero by 2050, a study by consulting firm McKinsey estimates that some $700 billion will need to be invested in hydrogen by 2030.

Once hydrogen has achieved a significant share of the global energy mix, there will be a huge need for storage capacities, just like the infrastructure available today for natural gas and oil. The equivalent of 25% of global demand needs to be constantly kept in storage, especially for countries' strategic reserves.

Pascal Baylocq, President and CEO of Geostock (VINCI Construction)

VINCI and low-carbon hydrogen production

Extract from the Leonard conference with Bruno Nicolas, Director of the Actemium brand (VINCI Energies), Hugues Seutin, Director of Hyfinity (VINCI Construction), and Pascal Baylocq, President and CEO of Geostock (VINCI Construction).

Most viewed

Explore more

Words from researchers: let's fight stereotypes!

Charlotte, a research fellow at École des Mines, and Erwan, a university professor and researcher at AgroParisTech, talk…

Fondation VINCI pour la Cité: opening the door to others is another way of reaching out!

With some 1.3 million organisations and 2 million employees, France can lay claim to a dynamic network of associations…

Sea water desalination: a solution for turning the tide on the water scarcity crisis?

As water shortages continue causing havoc in a growing number of regions around the world, an age-old idea is experiencing a…