Digital traceability – guaranteeing transparency for consumers

Consumers regularly look out for information about the origin of the products they buy. To respond to this increasing demand for transparency, which also concerns the environmental and social impact of production, manufacturers and producers supported by teams from VINCI are starting to focus on digital traceability. This article considers how it can be put in place.

Reassuring consumers – why are manufacturers and producers starting to focus on transparency?

Aggravated by scandals, mistrust among consumers is on the rise. Whether it’s the pharmaceutical industry with its technical vocabulary, the food-processing industry, or the fashion industry, companies across the board seek to reassure consumers concerned about product safety and business ethics. Transparency has become a major issue for manufacturers and producers. It empowers consumers to ensure the product they are considering buying was produced in a way they deem acceptable in terms of safety as well as social and environmental responsibility.

Digital traceability becoming essential to guarantee transparency within manufacturing

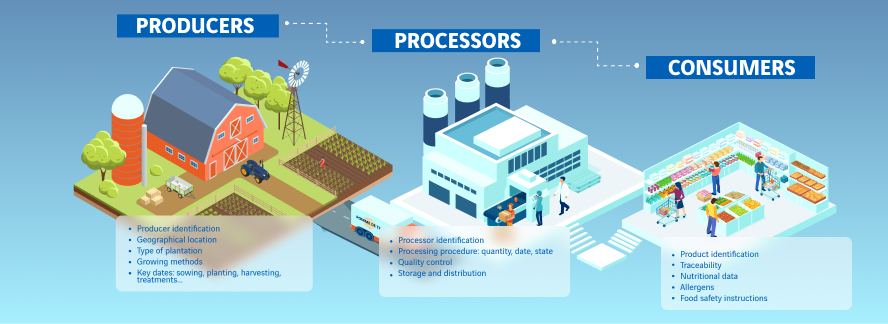

To improve transparency, manufacturers and producers are looking to digital traceability. By harnessing connected tools, such as a Manufacturing Execution System (MES), it is possible to track every stage of production and even distribution of a product. These tools are playing an increasingly prevalent role in the ongoing industrial revolution, which centres around data and processing in real time.

“In addition to enhancing productivity, digital traceability directly improves quality and risk control by minimising human error and fraud,” , explained Willem Van Overmeiren, Business Development Director at Actemium, a subsidiary of VINCI Energies's brand dedicated to industrial performance of its clients.

Digital traceability in the food processing industry

Aviko, a Dutch potato processing group, has set itself an objective to trace its products from the farm to the plate. This is where the traceability technology and solutions developed by Actemium, subsidiary of VINCI Energies, come in. By installing sensors on machines, we can collect data to either optimise plant production or precisely inform the end consumer about the origin and production stages of a product. If we take the example of the potato processing plant, the producer can see in real time where its raw material is coming from, to which plant it is being sent, how long it will take for the potato to be processed and to which retailer the products will be transported. The data is collected automatically and securely all throughout the processing journey, providing a genuine guarantee of transparency.

Digital traceability in the pharmaceutical industry

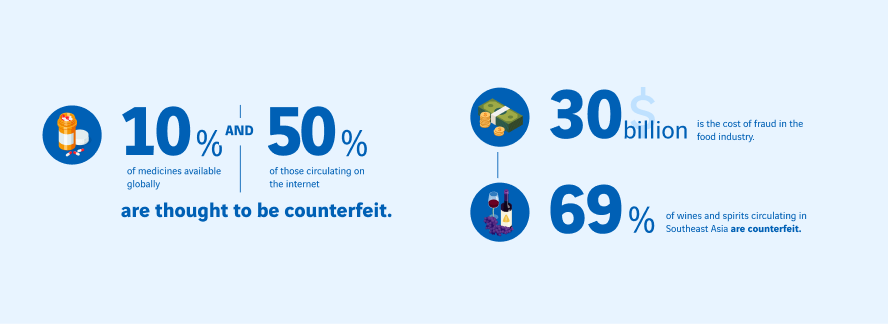

As it is estimated that 10% of medicines circulating worldwide are counterfeit, producers and public authorities are joining forces to minimise economic and public health risks. That is how the the pharmaceutical industry became one of the first to implement digital traceability systems and achieve compliance with the European standard. Indeed, in 2019, authorities in Europe introduced the requirement for all medicinal products to be identified and authenticated, meaning that every box of medicine receives a unique identification number, which is recorded in a European database. Scanning this identifier makes it possible to certify the origin of the box, and therefore to check that it comes from a factory and a company authorised to produce that particular medicine. The aim is twofold: to limit the falsification and traffic of medecines, to reduce the risks for patients who take products that are ineffective, or even harmful, for their pathology.

How blockchain can improve transparency and digital traceability

Already used in banking and cryptocurrency, blockchain technology can also serve other purposes. In manufacturing and production, food processing, or pharmaceuticals, this innovation can help to trace and secure supply chains and ever-more complex sub-contracting setups.

Blockchain is basically a digitally distributed, decentralized, public ledger that exists across a network. More specifically, blockchain users exchange data in real time without the need for any intermediaries. Once approved by all parties, the data forms a block, which takes its place in an immutable chain.

Let’s go back to the example of our potato to illustrate how blockchain can help traceability in the food processing industry. A farmer would indicate in the blockchain which farm and which harvest a batch of a given potato came from, as well as when it is handed over to a transporter for delivery; the transporter would confirm they had picked up the particular batch of potatoes and delivered it to the wholesale market; the wholesaler would report they had received the delivery from the transporter; the retailer would indicate they had received the delivery from the wholesaler; and the consumer would then buy the product and could find out exactly where it came from, tracing its journey all the way from farm to plate.

Every step of the process is approved and visible to all. The blockchain is then copied onto several servers, making it impossible to falsify without attracting attention.

This is how the retailer Carrefour has been operating since 2018, guaranteeing the traceability of chickens sold under its brand. At the end of the chain, the consumer can scan a QR code and access the entire certification sequence – including the date of birth of the chicken, the name and location of the farm, the date it was slaughtered, details of medical treatment it received, alongside any other important information.

This secure solution for digital traceability eliminates the need for any intermediary and gives the power back to the users, who all remain independent.

Most viewed

Explore more

Words from researchers: let's fight stereotypes!

Charlotte, a research fellow at École des Mines, and Erwan, a university professor and researcher at AgroParisTech, talk…

Fondation VINCI pour la Cité: opening the door to others is another way of reaching out!

With some 1.3 million organisations and 2 million employees, France can lay claim to a dynamic network of associations…

Sea water desalination: a solution for turning the tide on the water scarcity crisis?

As water shortages continue causing havoc in a growing number of regions around the world, an age-old idea is experiencing a…