Materials: innovations in low-carbon concrete!

Construction is a major emitter of greenhouse gases. In France, it is estimated to be responsible for 8% of emissions*, with these being linked to the fuel consumed by the machinery on site, but also and above all to the use of the materials. Most players in the building and public works sector have aligned their objectives with those of the 2015 Paris Agreement, aiming for carbon neutrality by 2050. Let's take a look at the various levers that will enable the sector to rise to the challenge of low-carbon construction, with a first look at concrete.

With annual production estimated at 14 billion m3, concrete is the most widely used construction material in the world. Pre-stressed, reinforced, cast, sprayed, etc. it adapts to all solutions and all contexts at a relatively modest cost compared with other materials.

Concrete: 8% of global greenhouse gas emissions

On the other hand, concrete alone is responsible for 8% of the world's greenhouse gas emissions. An observation that needs elaborating on its manufacturing process to understand it: It is made up of inert parts (sand or aggregates) mixed with an element whose physical and chemical properties bind these inert parts together. In the case of modern concrete, this is cement. Cement manufacture is a major emitter of greenhouse gases. What's at stake? Its main component is clinker, a material obtained by heating limestone and clays to 1,450°C, releasing a significant amount of CO2.

If it is to meet its commitments to reduce greenhouse gas emissions, the challenge for the construction sector is to reduce the use of clinker in cement. "When it comes to concrete, low-carbon mainly means 'low cement', or more precisely ‘low clinker’”, sums up François Cussigh, head of concrete materials engineering at VINCI Construction. While concrete can be replaced in the building industry with bio-sourced materials, such as wood or raw earth, it is still often essential in public works, such as when digging underground structures. Hence the need for the public works sector to use alternative cements.

Concrete is a fantastic material that needs to evolve. This transformation is underway. The cement culture is evolving rapidly, and so much the better.

Laurent Frouin, Ecocem Research and Innovation Director

Replacing clinker, the source of concrete CO2 emissions

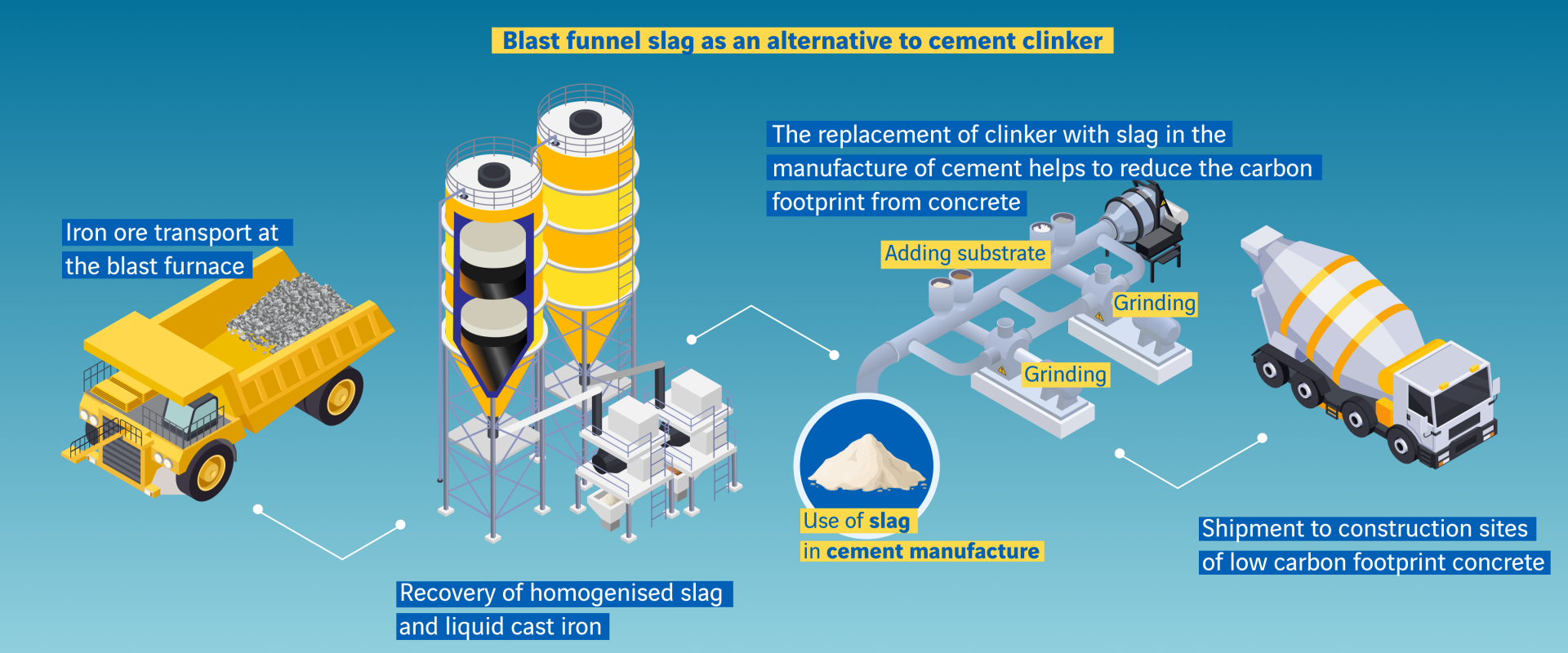

Fortunately, there are alternative solutions to clinker. Among these, ground blast furnace slag offers the best resistance qualities and the best environmental performance. This is an industrial waste product from the cast iron manufacturing process, with the same characteristics as clinker but with a much smaller carbon footprint. The production of alternative binders was developed and industrialised in the mid-2010s.

Using this waste product from the steel industry, VINCI Construction has designed, endorsed and marketed the range of Exegy® low-carbon concretes in partnership with Ecocem, the leading independent producer of ground blast furnace slag. Depending on the degree of substitution of clinker with blast furnace residues, the range of Exegy® concrete is available in low-carbon, very low-carbon and ultra-low-carbon versions. This gives a 70% reduction in CO2 emissions compared with traditional concretes, while guaranteeing the same technical resistance properties.

It is the partnership between suppliers of ground slag and construction companies such as VINCI that has led to the development of more environmentally-friendly concrete formulations. "Many VINCI Construction projects in France contain Ecocem ground slag. We started working with the teams in 2009, as soon as we launched our first French production site in Fos-sur-Mer. Various building, civil engineering and underground works operations gave us the opportunity to get to know each other," explains Laurent Frouin, Research and Innovation Director at Ecocem.

The rise in the use of low-carbon concrete on building sites

Exegy® low-carbon concrete has already been used in a number of VINCI projects. These include:

- VINCI's head office in Nanterre, where six structural columns carrying the load of eight storeys were cast using ultra-low carbon concrete;

- lot 1 of line 18 of the Grand Paris Express, where forty ultra-low carbon concrete voussoirs (prefabricated curved elements that form the lining of a tunnel) are installed: a world first for a metro! The aim is to work together with the Société du Grand Paris to test the strength of ultra-low carbon concrete underground, with a view to its widespread use;

- Phase III of the Port 2000 extension project for the port of Le Havre, where an ultra-low carbon concrete test block was poured at a depth of 17 m.

- the Universeine project, which will house the Athletes' Village in Saint-Denis, where 18,000 m3 of ultra-low carbon concrete was used;

- seven of the thirteen buildings of the new Nantes hospital for which all the concrete used is low or very low carbon, with a clinker substitution ranging from 50% to 80%.

In partnership with all the players in the sector, VINCI Construction aims to develop the use of these concretes for all types of structures, both buildings and infrastructure, and is committed to making their use widespread on its own worksites over the next decade, with a target of using 90% low-carbon concretes on all its worksites by 2030.

Most viewed

Explore more

Words from researchers: let's fight stereotypes!

Charlotte, a research fellow at École des Mines, and Erwan, a university professor and researcher at AgroParisTech, talk…

Fondation VINCI pour la Cité: opening the door to others is another way of reaching out!

With some 1.3 million organisations and 2 million employees, France can lay claim to a dynamic network of associations…

Sea water desalination: a solution for turning the tide on the water scarcity crisis?

As water shortages continue causing havoc in a growing number of regions around the world, an age-old idea is experiencing a…